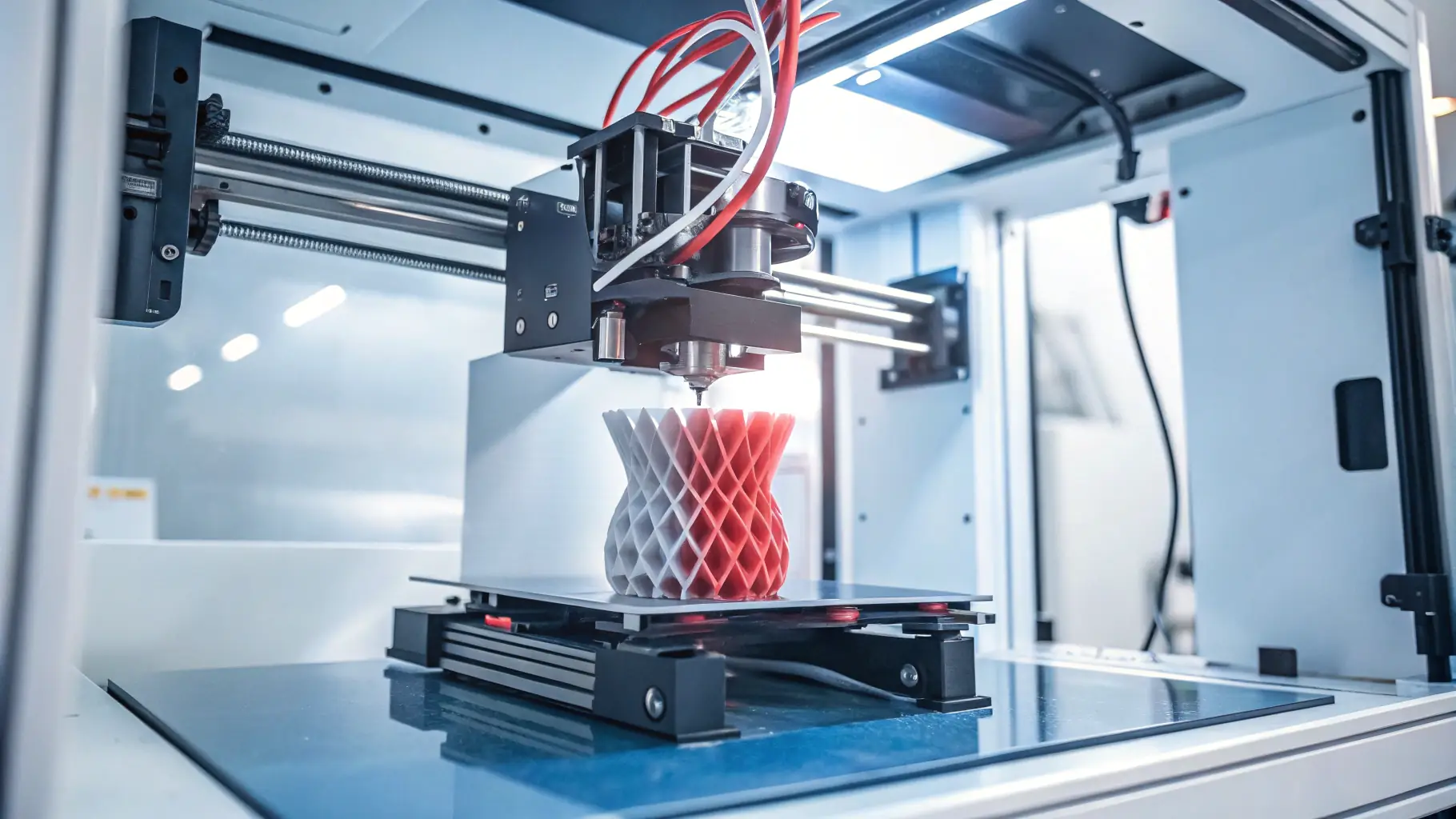

Additive manufacturing is rapidly evolving, with new technologies and materials emerging every day. As industries continue to adopt 3D printing, the potential applications are expanding beyond traditional boundaries. Companies are now exploring innovative ways to integrate additive manufacturing into their supply chains, enhancing efficiency and reducing costs. This article delves into the future of additive manufacturing, highlighting key trends that are set to transform the industry.

One of the most significant trends is the rise of bioprinting, which has the potential to revolutionize healthcare by enabling the creation of custom tissues and organs. Additionally, advancements in materials science are leading to the development of stronger, lighter, and more versatile materials for 3D printing. This opens up new possibilities for industries such as aerospace, automotive, and consumer goods. As these technologies continue to mature, businesses must stay informed to remain competitive in the market.

Moreover, sustainability is becoming a crucial consideration in additive manufacturing. Companies are increasingly seeking ways to minimize waste and reduce their environmental impact through responsible sourcing and efficient production methods. The future of additive manufacturing is not just about innovation; it’s also about creating a sustainable and responsible manufacturing ecosystem. By embracing these trends, businesses can position themselves for success in the evolving landscape of additive manufacturing.